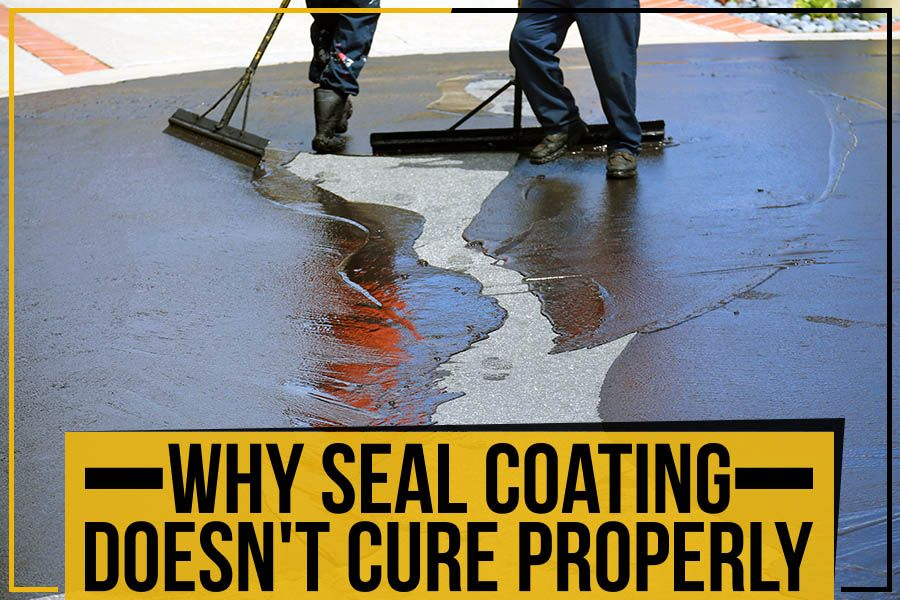

Sealcoating is an essential component of routine maintenance of asphalt driveways. It creates a barrier between the pavement surface and the factors that can damage it, like rain, snow, ice, and UV rays.

Several seal coat products are on the market, but not all work as advertised. In some cases, a seal coat will fail to cure correctly, leading to severe problems down the road. If you’re considering seal coating your driveway, it’s essential to research and find a product that will give you the best results.

This blog post by Straight Edge Contractors LLC discusses why a seal coat may not cure properly.

Common Mistakes:

The seal coating procedure demands patience and meticulousness. But even if you follow all the instructions to a T, things can still go wrong. Here are a few frequently made blunders by homeowners when applying a seal coat to their roadways:

- Applying the sealant too thick or too thin

- Not allowing enough time for the sealant to dry

- Seal coating in direct sunlight

The Required Time and Temperature:

A seal coat should be applied when the temperature is between 60 and 90 degrees Fahrenheit. If it’s too cold, the seal coat won’t cure properly. If it’s too hot, the seal coat will evaporate before it has a chance to cure.

Not only must the temperature be precise, but you must also allow enough time for the seal coating to dry. Depending on the product you use, this can take 24 hours to 72 hours.

If you don’t have time to wait around for the perfect weather conditions, there are products on the market that can be used in a broader range of temperatures. However, these products usually come with a shorter curing time, so you’ll need to be extra careful not to damage the seal coat while it’s still curing.

Why Doesn’t the Seal Coat Cure Properly?

An inadequately cured seal coat is more susceptible to damage and wear and tear. This means that it won’t be able to protect your asphalt, and it will need to be replaced more often.

Here are a few reasons why the seal coat might not cure properly:

Use of Substandard Material:

If you use a substandard material, it’s likely that the seal coat won’t cure properly. This is because the material might not be able to withstand the elements, or it might not be compatible with the asphalt. An example of a substandard material is using an asphalt emulsion with a low softening point.

Incorrect Storage of Material:

The right way to store the seal coat material is in a cool, dry place. If it’s stored in an area that’s too hot or too cold, it can affect the material’s ability to cure properly.

Improper Mixing:

Mixing is a significant part of the seal coating process, and if it’s not done correctly, the seal coat won’t cure properly. It is because the material needs to be mixed in the right proportions to be effective. The recommended ratio is two parts asphalt to one part sealer.

Inadequate Preparation of the Surface:

No amount of emphasis is less on the importance of preparing the surface before seal coating. If the surface isn’t prepped correctly, it can cause the seal coat not to adhere correctly, which will lead to premature failure.

Ending Note:

So, what can you do to make sure your seal coat cures properly? Start by hiring a reputable contractor, such as Straight Edge Contractors LLC in Midland, TX.

Seal coating is an integral part of keeping your asphalt in good condition, so don’t wait until it’s too late.